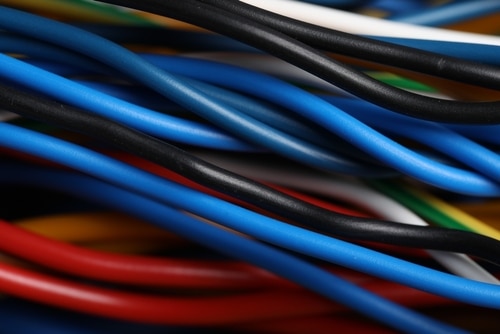

Wire & Cable Market Solutions

Mercury Plastics supports wire and cable manufacturers exclusively through electron beam irradiation crosslinking. By crosslinking insulation and jacketing materials, Mercury helps manufacturers meet demanding thermal, mechanical, electrical, and regulatory performance requirements.

With decades of experience and high-energy electron beam capacity, Mercury delivers precise, repeatable crosslinking for wire and cable products where consistency, compliance, and reliability are critical.

Solving Performance and Compliance Challenges in Wire & Cable

Wire and cable products operate in environments where material performance directly impacts safety, reliability, and service life. Manufacturers must meet stringent industry and OEM specifications while maintaining consistency across high-volume production.

Common challenges include:

Precise Crosslink Density Control

Electrical insulation and jacketing materials require tightly controlled crosslink density to achieve the correct balance of flexibility, strength, and heat resistance. Variability can lead to performance issues or failed compliance testing.

Thermal and Electrical Performance Requirements

Wire and cable constructions must withstand elevated temperatures, continuous electrical loads, and long service lifecycles without degradation, deformation, or loss of insulating properties.

Chemical, Abrasion, and Environmental Resistance

Many applications demand resistance to oils, chemicals, moisture, UV exposure, and physical wear, often in harsh industrial or outdoor environments.

Consistency at Production Scale

Even small variations in crosslinking can affect product performance. Manufacturers need repeatable, validated processing across every run.

Evolving Industry and Regulatory Standards

Wire and cable products must meet UL, CSA, OEM, and application-specific specifications that continue to evolve with new materials and technologies.

Wire & Cable Applications

Mercury Plastics provides electron beam crosslinking services for a wide range of wire and cable constructions, including:

Insulation materials crosslinked to improve thermal stability, electrical performance, and mechanical strength

Cable jacketing crosslinked for enhanced durability, flexibility, and environmental resistance

Heat trace cable constructions requiring precise, repeatable crosslinking performance

Specialty wire and cable designs with application-specific electrical, thermal, or chemical requirements

These solutions support industrial, commercial, and specialty electrical applications where material performance and compliance are non-negotiable.

Our Approach

Precise Electron Beam Crosslinking for Wire & Cable

Wire and cable performance depends on how materials are crosslinked. Mercury Plastics focuses exclusively on delivering controlled, high-quality electron beam crosslinking for wire and cable products.

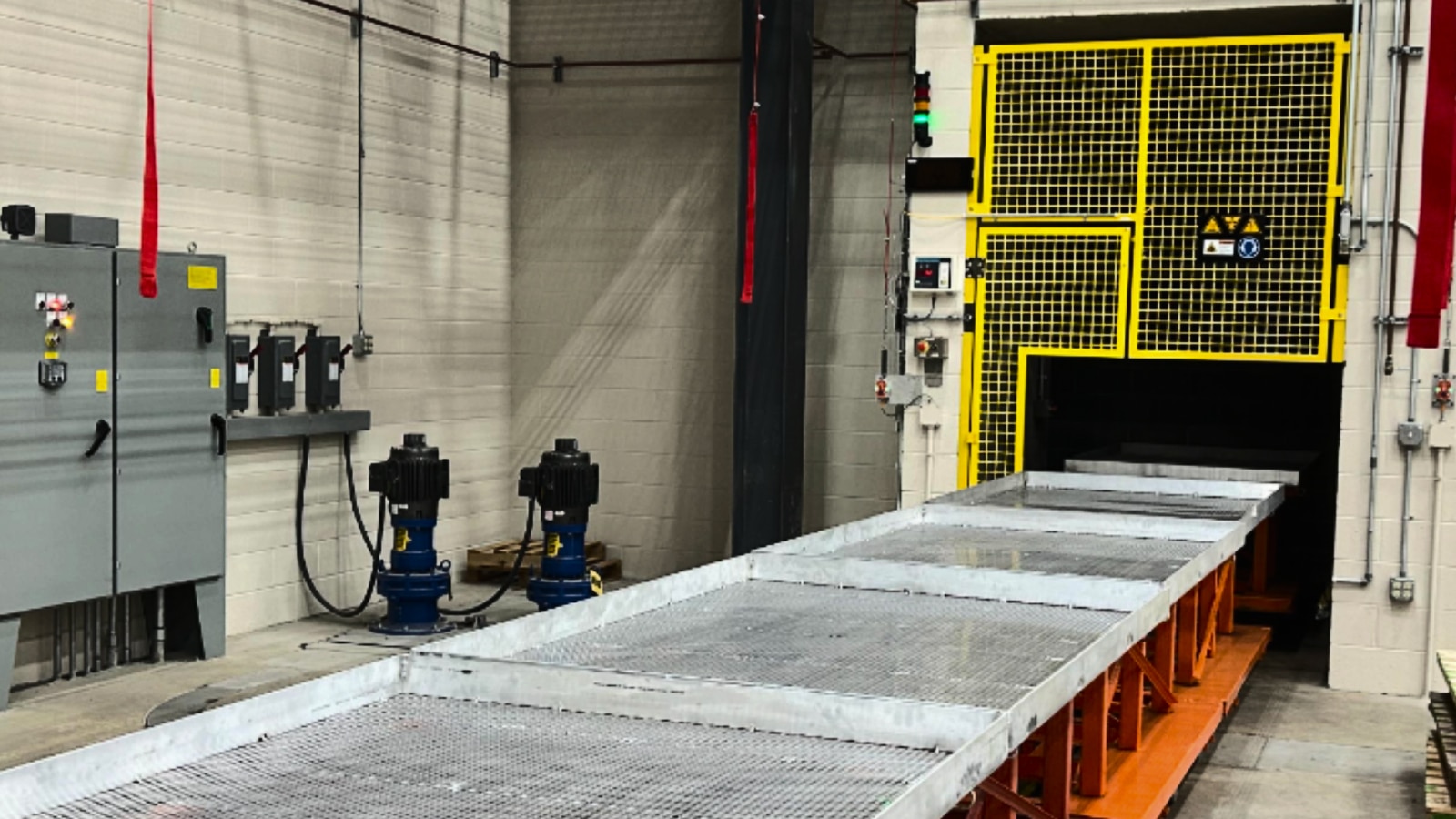

Electron Beam Crosslinking Expertise

Mercury operates dedicated, in-house electron beam (e-beam) processing systems with decades of experience supporting wire and cable manufacturers. Our capabilities include both 5 MeV and 10 MeV electron beam accelerators, a reel-to-reel material handling system, efficient processing techniques, the ability to process a wide range of wire & cable sizes, and precise dose control.

E-beam crosslinking enhances thermoplastic materials by improving:

- Heat resistance

- Mechanical strength

- Chemical resistance

- Abrasion and wear resistance

- Weathering and UV resistance

The process does not require chemical additives, resulting in a clean, controlled crosslinking method with no residual chemicals.

Process Control and Repeatability

Mercury’s electron beam operations are designed for consistency and validation. Tight control of dose, penetration, and processing parameters ensures repeatable results across high-volume production programs.

This level of control is especially valuable for manufacturers who:

- Require consistent performance to meet specifications

- Operate in regulated or safety-critical applications

- Need confidence that every run meets the same performance criteria

Capacity and Overflow Support

Many wire and cable manufacturers have in-house crosslinking capability but face limitations in beam power, throughput, or available capacity. Mercury serves as a reliable partner for:

- Production overflow

- Capacity expansion without capital investment

- Meeting aggressive timelines or peak demand

Engineering Support Focused on Crosslinking Performance

Mercury’s engineering team works directly with wire and cable manufacturers to optimize crosslinking performance and ensure products meet application-specific requirements.

Our engineers support clients by:

- Evaluating material behavior under electron beam irradiation

- Optimizing dose levels to achieve target performance properties

- Supporting testing and validation against industry and OEM specifications

- Assisting with process refinement for both new and existing products

This collaborative, performance-driven approach helps manufacturers improve product reliability while reducing risk and variability.

Get Started with Mercury Plastics

Discover how Mercury Plastics can help you improve product performance, reduce costs, and accelerate time-to-market.